Introduction

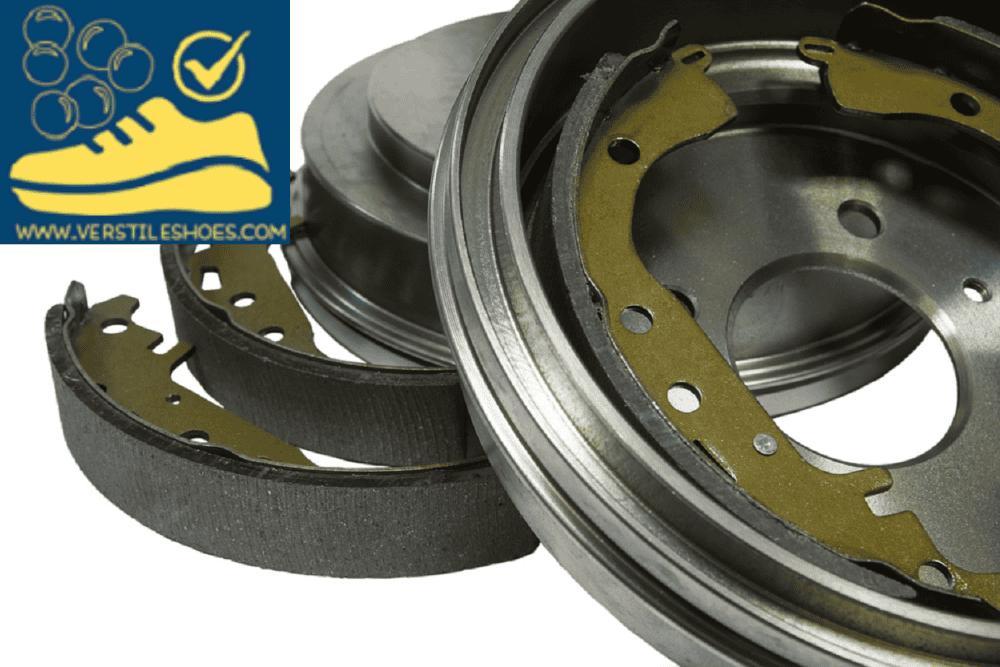

If you love driving and have your own vehicle, then you must know about difference between 4707 and 4515 brake shoes. Brake shoes are vital components in drum brake systems and very important for decelerating vehicles. They consist of a curved metal piece lined with friction material.

As the wheel cylinder forces them against the drum, friction generates the necessary resistance to slow down or stop the vehicle. These shoes undergo substantial wear and tear over time due to their role in braking.

When comparing the difference between 4707 and 4515 brake shoes, notable differences emerge. Both serve similar functions, but their designs and specifications vary. The 4707 brake shoes are typically larger in size. It is suitable for heavy-duty vehicles like trucks and buses. Brake shoes offer enhanced stopping power and durability.

On the other hand, the 4515 brake shoes are more commonly found in lighter vehicles such as passenger cars. It offers efficient braking for everyday driving scenarios.

Understanding the difference between 4707 and 4515 brake shoes is very important for selecting the appropriate component based on vehicle type and intended usage. In this guidance, you can easily understand the major difference between 4707 and 4515 brake shoes.

Whether it’s ensuring safety on the road or optimizing braking performance. Choosing the right brake shoes is essential for vehicle maintenance and operation.

What are the Major Difference between 4707 and 4515 Brake Shoes?

The 4707 brake shoes are wider compared to the 4515 ones. The 4707 shoes have a larger friction surface area and improved braking performance. However, the 4515 shoes may offer better compatibility with certain vehicle models due to their narrower design.

When you think of choosing brake shoes for your vehicle. Then it is very important for you to know about some of their difference between 4707 and 4515 brake shoes. The purpose of using both shoes is the same as 4707 and 4515 shoes are used for all kinds of vehicle brakes.

Size and Fit

4707 brake shoes are larger and wider compared to 4515 brake shoes. It makes them suitable for heavier vehicles and applications requiring more stopping power. The size variation affects how they fit within the brake drum assembly.

Friction Material

4515 brake shoes typically use a different friction material composition compared to 4707 shoes. This variance affects braking performance, heat dissipation and overall durability under different operating conditions.

Weight and Mass

The weight of 4707 brake shoes is typically higher than that of 4515 shoes due to their larger size and additional material. This disparity can influence braking dynamics and wear patterns over time.

Heat Dissipation

Due to their size and mass, 4707 brake shoes may dissipate heat differently compared to 4515 shoes. This distinction can impact brake failure performance under heavy braking and longevity in demanding conditions.

Compatibility

The two types of brake shoes may not be interchangeable due to differences in size, shape and configurations. Compatibility with specific vehicle models and brake drum assemblies must be considered when selecting difference between 4707 and 4515 brake shoes options.

Brake Drum Interaction

The interaction between the brake shoes and the brake drum may vary difference between 4707 and 4515 brake shoes options. Factors such as contact surface area, pressure distribution and wear patterns can differ affecting overall braking effectiveness.

Application

4707 brake shoes are commonly found in larger vehicles such as trucks, buses and heavy-duty trailers. Whereas 4515 shoes are often used in smaller trucks, vans and passenger vehicles. The intended application influences the design and performance characteristics of each shoe type.

Performance Characteristics

The performance characteristics including braking efficiency, noise levels and response time may difference between 4707 and 4515 brake shoes. These variances are influenced by factors such as friction material composition, surface area and heat dissipation capabilities.

Wear and Tear

The rate of wear and tear on 4707 brake shoes may differ from that of 4515 shoes due to variations in size, material composition and operating conditions. Understanding these differences is very significant for maintenance planning and replacement intervals.

Regulatory Compliance

Both difference between 4707 and 4515 brake shoes must meet specific regulatory standards for safety and performance. However, the requirements may vary depending on factors such as vehicle weight class, intended use and regional regulations.

Manufacturing Process

The manufacturing processes for 4707 and 4515 brake shoes may differ in terms of materials used, production techniques and quality control measures. These variations can impact product consistency, reliability and cost.

Cost and Availability

Due to differences in size, materials and demand, the cost and availability of 4707 and 4515 brake shoes may vary. Factors such as production volume, market demand and distribution channels influence pricing and accessibility for each type of brake shoe.

A Closer Look difference between 4707 and 4515 brake shoes: Making the Right Selection for You

Which shoes are suitable for which vehicles for this we need to complete a review of major differences between 4707 and 4515 brake shoes. Some key points keep in your mind for making the right selection for you.

1. Understanding Brake Shoes

- · 4707 vs. 4515

- · Comparing the Basics: Size and Fit

- · Analyzing Material Composition

2. Performance Factors

- · Heat Resistance and Durability

- · Examining Heat Dissipation Abilities

- · Evaluating Longevity and Wear Resistance

3. Friction Coefficient

- · Impact on Stopping Power

- · Assessing Frictional Properties

- · Considering Braking Efficiency

4. Compatibility

- · Matching with Your Vehicle

- · Checking Compatibility with Drum Size

- · Ensuring Proper Installation

5. Cost vs. Value

- · Budget Considerations

- · Weighing Initial Cost against Long-Term Savings

- · Considering Maintenance and Replacement Expenses

6. User Reviews

- · Insights from Real Experiences

- · Gauging User Satisfaction and Feedback

- · Learning from Practical Experiences

Advantages of difference between 4707 and 4515 Brake Shoes

| Advantages of 4707 Brake Shoes | Advantages of 4515 Brake Shoes |

| Enhanced stopping power | Improved durability |

| Optimal heat dissipation | Consistent performance |

| Reduced brake fade | Longer lifespan |

| Better resistance to wear | Enhanced braking efficiency |

| Improved brake pad longevity | Greater reliability |

| Suitable for heavy-duty use | Effective in various conditions |

| Quick and easy installation | Low maintenance requirements |

| Wide availability | Cost-effective solution |

Disadvantages of difference between 4707 and 4515 Brake Shoes

| Disadvantages of 4707 Brake Shoes | Disadvantages of 4515 Brake Shoes |

| Limited compatibility with newer brake systems | Limited availability in some markets |

| May not provide optimal performance on modern vehicles | Less effective braking performance compared to newer designs |

| Potentially difficult to find replacement parts | May not meet current safety standards |

| Heavier compared to more advanced brake shoe designs | Higher risk of brake fade under heavy usage |

| Can be prone to premature wear and tear | Limited compatibility with upgraded braking systems |

Special Tips to Maintenance the 4707 and 4515 Brake Shoes

No matter which brake shoe type you pick. It’s important to maintain them well for safety and top performance. Here are some easy tips for keeping your 4707 and 4515 brake shoes in good shape.

Regular Check-up: Check the brake shoes regularly for wear and tear. Look for any signs of damage or uneven wear that may affect performance.

Cleanliness Matters: Keep the brake shoes clean from dirt, debris, and brake dust build-up. Use a brush or compressed air to remove any particles.

Proper Lubrication: Apply a thin layer of high-temperature grease or lubricant to the contact points between the brake shoes and other components to ensure smooth operation.

Adjustment Checks: Periodically check the adjustment of the brake shoes to maintain proper clearance and ensure efficient braking. Adjust as needed according to the manufacturer’s specifications.

Avoid Overheating: Be mindful of heavy braking, especially during long descents or when carrying heavy loads, as overheating can damage the brake shoes. Allow them to cool down if they become excessively hot.

Replace When Necessary: Replace the brake shoes promptly if they are worn beyond the recommended limit or if there are any signs of damage that cannot be repaired. This ensures continued safety and optimal braking performance.

Bottom Lines

Understanding the difference between 4707 and 4515 brake shoes is essential for making informed decisions about vehicle maintenance and safety. The 4707 brake shoes, with their larger size and enhanced stopping power are suitable for heavy-duty vehicles like trucks and buses.

Whereas the 4515 brake shoes are more commonly found in lighter vehicles such as passenger cars. It offers efficient braking for everyday driving scenarios. Differences in size, friction material composition, weight, heat dissipation compatibility affect their performance and suitability for various applications.

Regular maintenance, including checking for wear and tear, cleanliness, proper lubrication, adjustment and timely replacement is essential to ensure optimal performance and safety. By considering these factors, drivers can select the right brake shoes for their vehicles. It ensures reliable braking performance and vehicle operation.

Whether it’s ensuring safety on the road or optimizing braking performance, choosing the right brake shoes is essential for vehicle maintenance and operation.

Related Posts

How to Break in Wrestling Shoes: The Art of Breaking in Wrestling Shoes

Can Patent Leather Be Stretched: Techniques and Tips for Survival 2024

FAQs

What are the main differences between 4707 and 4515 brake shoes?

The main differences lie in size, application, friction material, and compatibility, impacting braking performance and suitability for various vehicles.

Which vehicles are typically suited for 4707 brake shoes?

4707 brake shoes are suitable for heavy-duty vehicles like trucks, buses, and trailers due to their larger size and enhanced stopping power.

What maintenance tips apply to both 4707 and 4515 brake shoes?

Regular check-ups, cleanliness, proper lubrication, adjustment, and timely replacement are crucial for ensuring optimal performance and safety for both types of brake shoes.

What advantages do 4515 brake shoes offer over 4707?

4515 brake shoes provide improved compatibility with modern vehicles, consistent performance, and may offer better braking efficiency in certain conditions.

How do the weight and size of 4707 brake shoes differ from 4515?

4707 brake shoes are larger and heavier compared to 4515, making them suitable for heavier vehicles and applications requiring more stopping power.